How to Increase the Cone Crusher Capacity

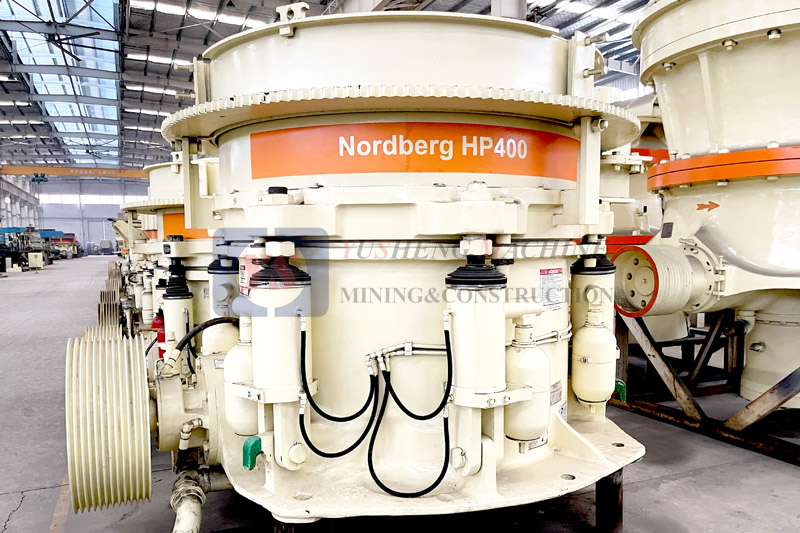

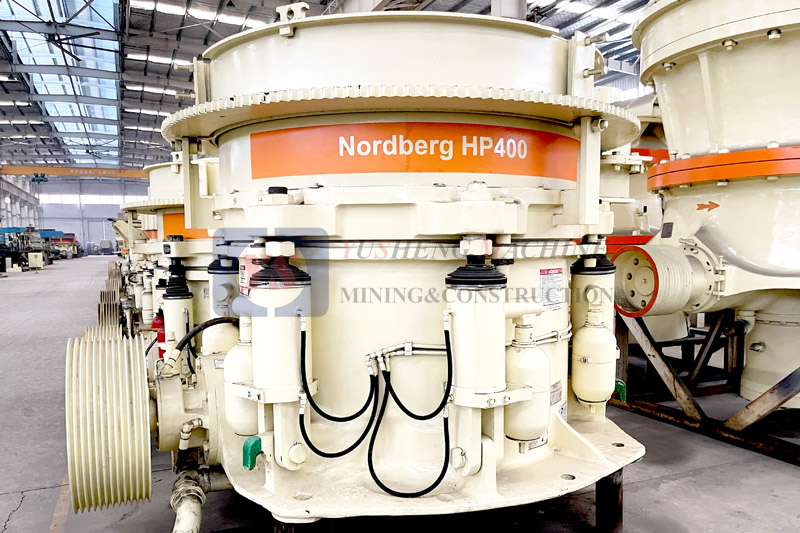

The crawler mobile cone crushing plant produced by Henan Yusheng Machinery can be matched with various crushing cavity types according to the customer's requirements for material processing, which makes it have the characteristics of high output, good product shape and low cost of wear parts in any application. In addition to the capacity of the plant itself, paying attention to some details in the process of production operation can better enhance the output and bring out the maximum economic efficiency of the plant.

I.Production operation details

Uniform crowding during feeding

Usually, since the conveyor speed is constant, all that can be selected is the drop height of the ore. When installing the feeding device, it is necessary to pay attention to the speed of the ore when it enters the crusher and the corresponding drop relationship. While crowding the ore feed, pay attention to the feed cannot be more and less at the same time, and control the height of the ore pile in the feeding device.

2. Control the speed of the belt conveyor

When feeding, the material should be in line with the corresponding feeding volume of the cone crusher. The operator needs to pay high attention to the discharge port of cone crusher and control the speed of belt conveyor to feed the material evenly to ensure the normal feeding as well as discharge.

3. Adjust the size of the closed edge discharge opening according to the demand

The size of the closed edge discharge opening can be adjusted according to the actual demand. When the size of the closed side discharge opening is larger, the higher the output of the cone crusher, the worse the quality of the finished product; on the contrary, the smaller the size of the closed side discharge opening, the smaller the output, the better the quality of the finished product.

4. Timely replacement of the dust seal ring

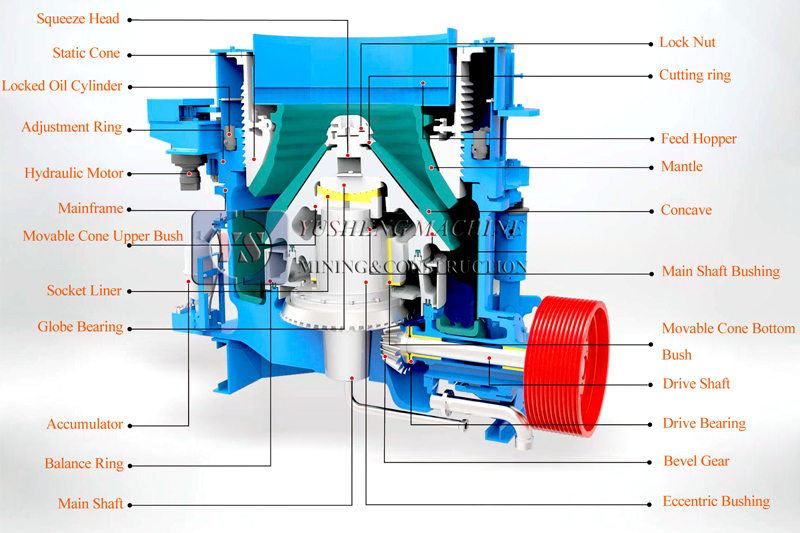

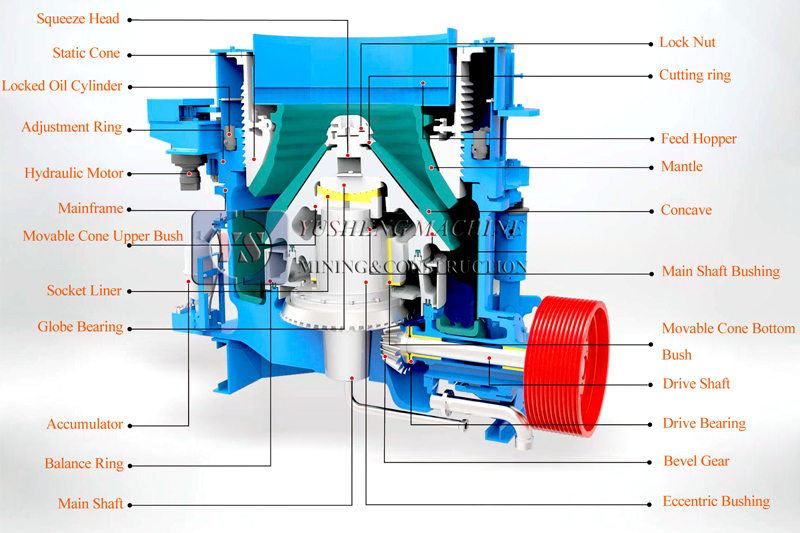

Each time the liner is replaced, to detect the dynamic cone dust seal is intact. Usually, the wear gap between the dust seal ring and the sliding ring is greater than 1.5mm when the dust seal ring should be replaced to prevent damage to the spindle and other parts caused by mineral powder entering the cylinder liner.

5. Select the appropriate cooling and heat dissipation device

Since the lubrication and heat dissipation of the main lubrication parts of the crusher, such as the main shaft, eccentric sleeve, eccentric shaft, frame bearing and main shaft adjusting piston, sliding bearing surface, gear rotation, etc., mainly depend on the lubrication system to complete, so it is very important to choose a suitable cooling and heat dissipation device.

II.1. Regularly check the water cooler, filter and oil pump

Regularly check the water cooler, filter and oil pump of the cone crusher machine, measure the oil temperature, in general, the return oil temperature is required not to exceed 60 degrees, the temperature is too large for the equipment is harmful.

2. Regularly check the drainage of water seal and dustproof

Regularly check the drainage of water seal and dustproof of cone crusher, once you find no water or very little water, you should stop in time, otherwise it will seriously affect the equipment;

3. Regularly check the oil pressure of the locking cylinder

Every time, the operator should check the oil pressure of the locking cylinder of the cone crusher, especially in the case of serious liner wear, more attention should be paid to the liner fixing bolts on the adjusting ring, once loosened, it will cause the liner to loosen. For the newly replaced liner, it needs to be tightened once after 24 hours of work.

To sum up: Yusheng crawler mobile cone crushing plant has the characteristics of high output, good product granularity and low cost of wear parts. Paying attention to the details of production operation and regular inspection of equipment can not only prolong the service life, but also determine whether it can have high output and high efficiency.