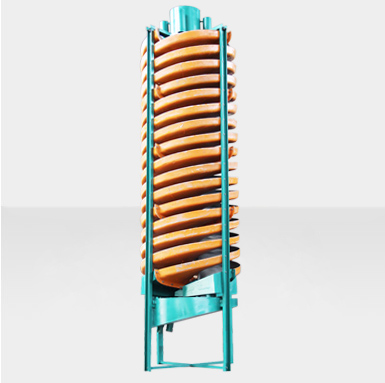

Model

Specification

Input Size(mm)

Rotate Speed (r/min)

Power(kw)

Weight(t)

|

Model |

Specification |

Input Size(mm) |

Rotate Speed (r/min) |

Power(kw) |

Weight(t) |

|

1600A |

1600x400x200x500±20mm |

<30mm |

20-22 |

25KW |

14.5 |

|

1500A |

1500x350x200x460±20mm |

20-22 |

22KW |

13.5 |

|

|

1500B |

1500x350x150x460±20mm |

20-22 |

22KW |

12.3 |

|

|

1500C |

1500x300x150x420±20mm |

20-22 |

22KW |

11.3 |

|

|

1400A |

1400x250x150x350±20mm |

16-18 |

18.5kw |

8.5 |

|

|

1400B |

1400x250x150x350±20mm |

21-23 |

18.5kw |

8.5 |

|

|

1350A |

1350x250x150x350±20mm |

16-18 |

18.5kw |

8 |

|

|

1350B |

1350x250x150x350±20mm |

21-23 |

18.5kw |

8 |

|

|

1300A |

1300x250x150x350±20mm |

16-18 |

15kw |

7.5 |

|

|

1300B |

1300x250x150x350±20mm |

21-23 |

15kw |

7.5 |

|

|

1200A |

1200x200x80x250±20mm |

17-19 |

7.5kw |

5.5 |

|

|

1200B |

1200x200x80x250±20mm |

23-25 |

7.5kw |

5.5 |

|

|

1100A |

1100x200x80x250±20mm |

17-19 |

7.5kw |

5 |

|

|

1100B |

1100x200x80x250±20mm |

23-25 |

7.5kw |

5 |

|

|

1000 |

1000x200x80x250±20mm |

13-15 |

5.5kw |

4.5 |

|

|

900 |

900X200X80 |

10-15 |

5.5kw |

3 |